Dry etching

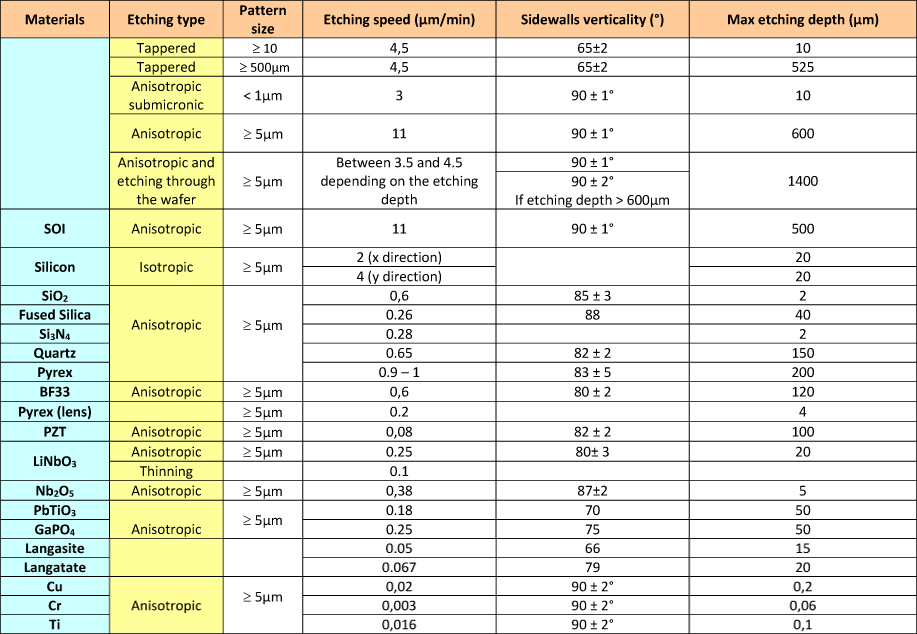

MIMENTO technology center has a resource dedicated to the dry etching of different materials (plasma etching). A key feature of plasma etching is the ability to etch materials, isotropic or anisotropic, independent of the crystal orientation.

In plasma etching, the gas entering the reactor will be ionized and fragmented by electric or magnetic excitation, generating electrons, ions, radicals and molecule fragments. By diffusion or drift they reach the sample surface, where they undergo chemical (radicals, molecule fragments) or physical (energetic ions) interactions with the sample. In this way, the sample surface can be etched.

By choosing the appropriate reactive gases (SF6, CF4, C4F8, Ar….), a wide range of materials can be etched (Silicon, Quartz, Glass, LiNbO3, ...).

Depending on the chosen process, the etched depth varies from few nanometers to the through etching of the wafer.

Resource contact:

| Djaffar BELHARET 03 81 66 55 83 djaffar.belharet [at] femto-st.fr |

Personal page: https://www.femto-st.fr/fr/personnel-femto/djaffarbelharet |

| Samuel QUESTE 03 63 08 66 47 samuel.queste [at] femto-st.fr |

Personal page: https://www.femto-st.fr/fr/personnel-femto/samuelqueste |

Asher & Surface treatment system

| Nanoplas DSB 6000 |

Use: > PR stripping > Surface treatment, prep-aration, functionalization |

|

Technical specifications |

——

Stripping tool

| Muegge R3T |

Use: > Thick photoresist remover (SU8), descum and surface Activation |

|

——

RIE-CCP system

| CORIAL 200-R |

Use: > Nano-metric & sub-µ etching on variety of materials |

|

Technical specifications |

——

Si DRIE-ICP system 4’’

| Alcatel 601E |

Use: > Si deep etching > Si isotropic etching |

|

Technical specifications |

——

Si DRIE-ICP system 4’’

| SPTS Rapier |

Use: > Si deep, sub-micronic & isotropic etching > Vias etching |

|

Technical specifications |

——

Si DRIE-ICP system 6’’

| SPTS Rapier Omega C2L |

Use: > Si deep, sub-micronic & isotropic etching > Vias etching |

|

Technical specifications |

——

Multi-material DRIE-ICP system 4’’

| STS APS |

Use: > Dielectric, isolated & piezo-electric materials etching |

|

Technical specifications |

——

Chlorine ICP system 4’’

| Trikon Omega 201 |

Use: > Metallic materials & SC materials etching |

|

Technical specifications |

——

Dry etching overview

——

Realisations

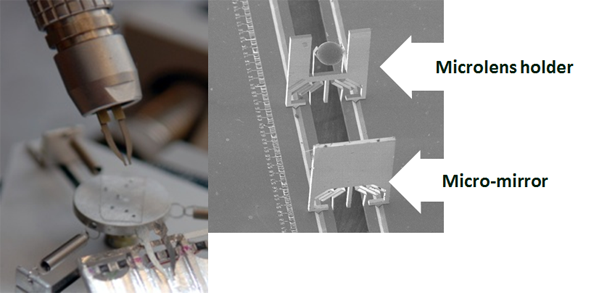

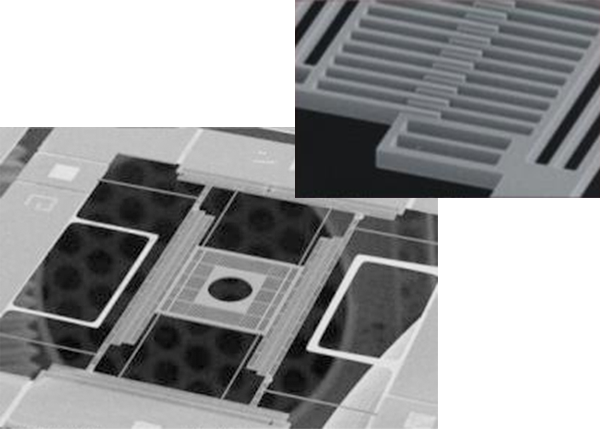

Micro-assembly of micro-optical components

Micro-assembly of micro-optical components

Electrostatic X-Y microactuator

Electrostatic X-Y microactuator

|

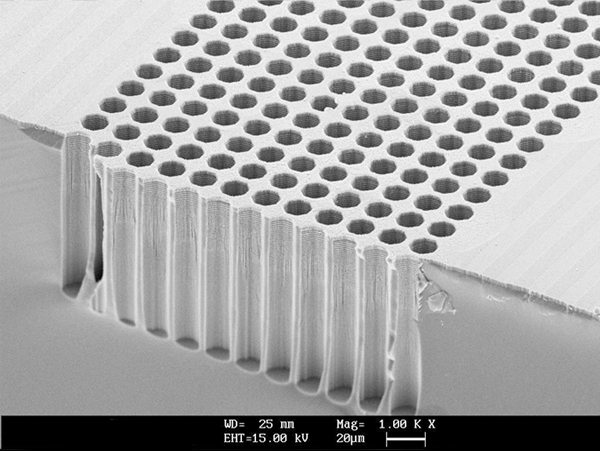

Phononic crystals

Phononic crystals

|