Dicing / Polishing

This resource, located out of clean room merge two complementary thematics, materials precision dicing and lapping/polishing.

- Dicing allows chips separation but also materials structuration via various blades shapes and dicing parameters.

- Polishing improve the surface quality of many materials. It's also possible to reduce sample thickness up to very thin dimensions by hard or soft lapping.

Resource contact:

| Ludovic GAUTHIER-MANUEL 03 63 08 24 36 ludovic.gauthier [at] femto-st.fr |

Personal page: https://www.femto-st.fr/fr/personnel-femto/ludovicgauthier |

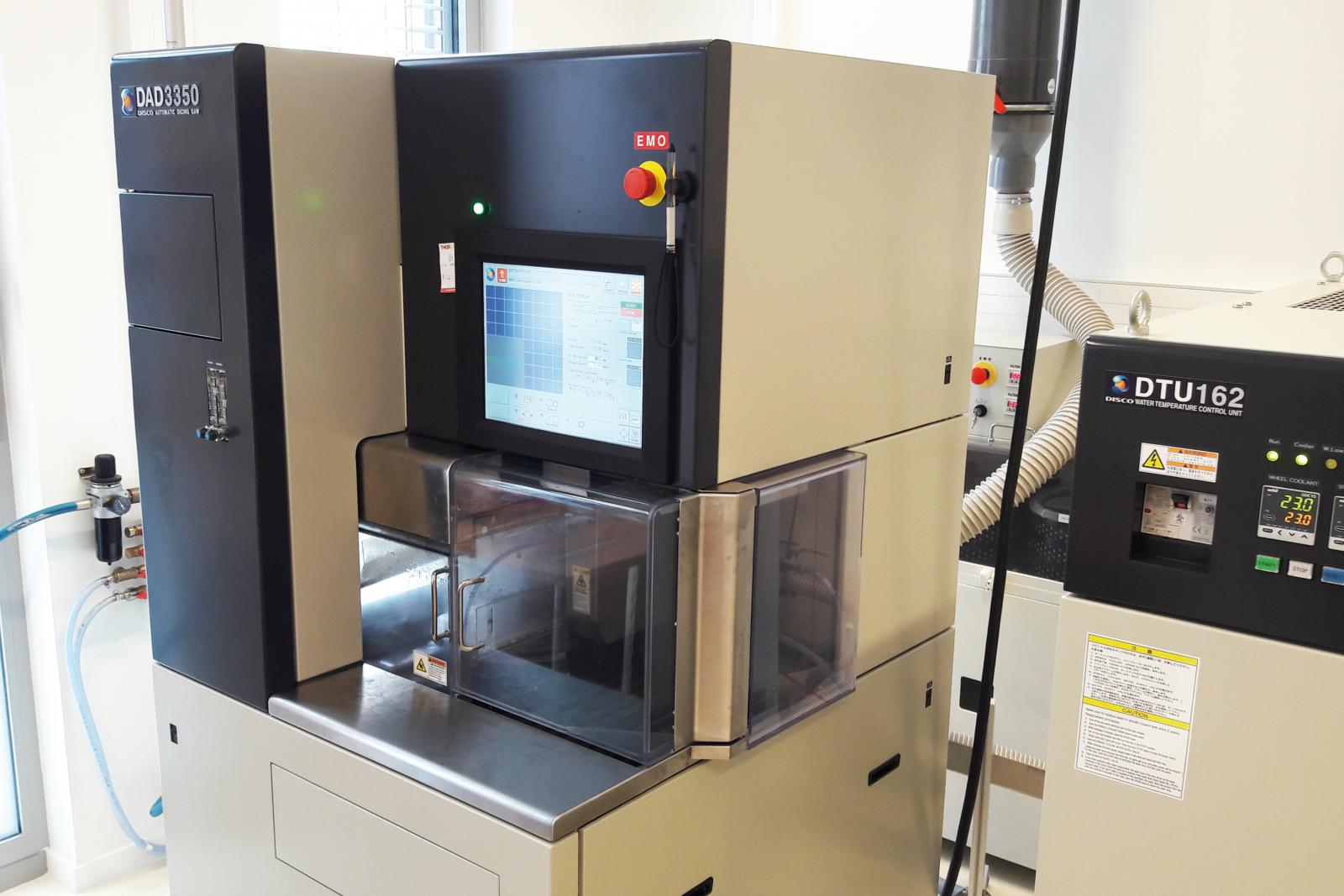

High Precision Dicing Saw 8"

| Disco DAD 3350 |

Use: > Separation & Structuration of chips > Circle cut process |

|

Technical specifications |

——

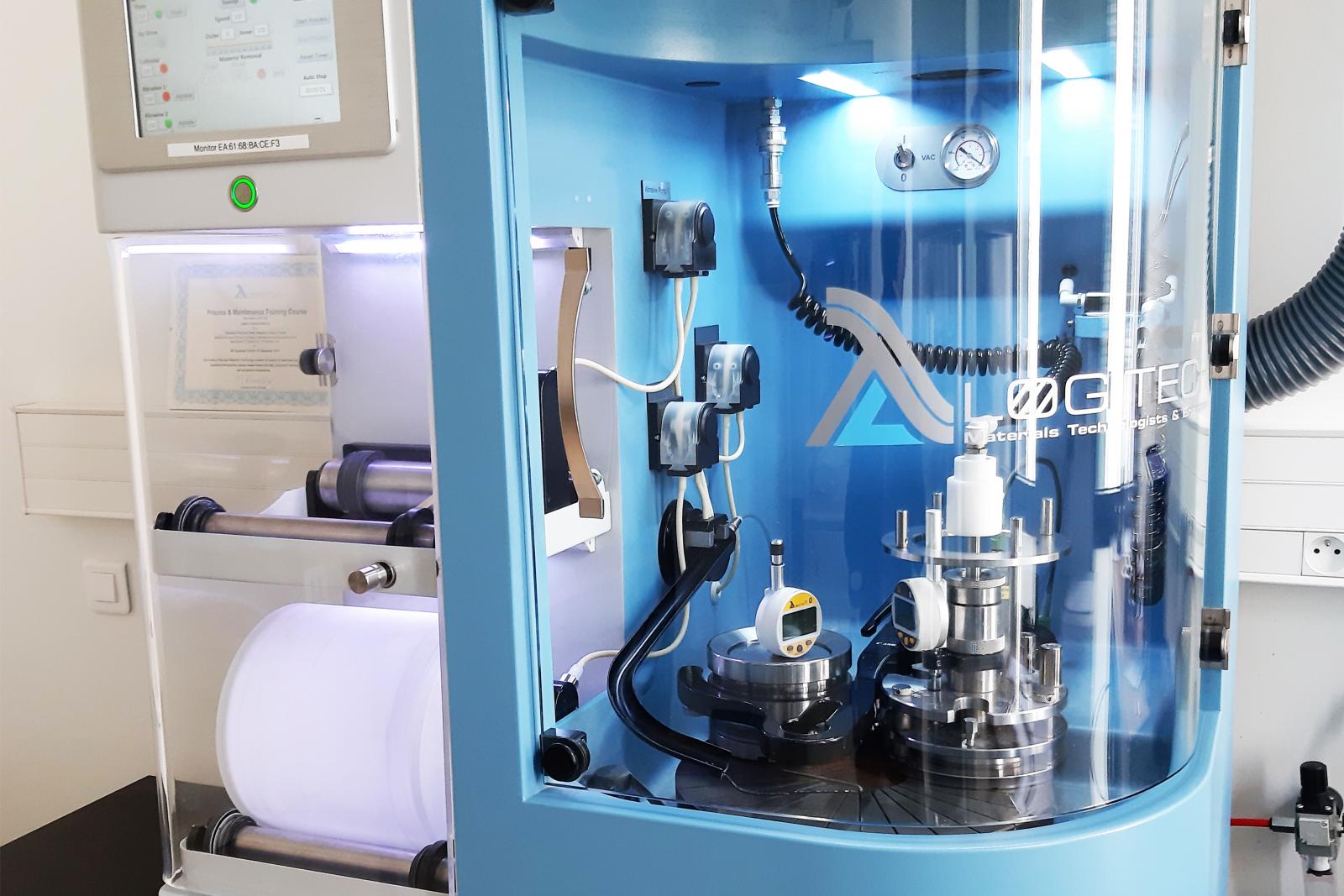

Precision Lapping & Polishing system

| Logitech PM6 |

Use: > Optical polishing > Material thinning |

|

Technical specifications |

——

CMP system

| Alpsitec E460 |

Use: > Wafer optical polishing > Hard materials process |

|

Technical specifications |

——

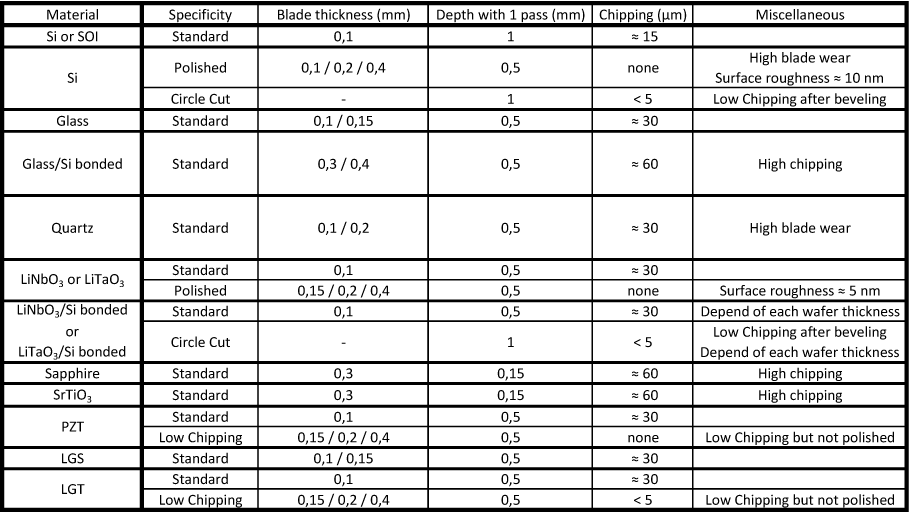

Dicing overview

——

Realisations

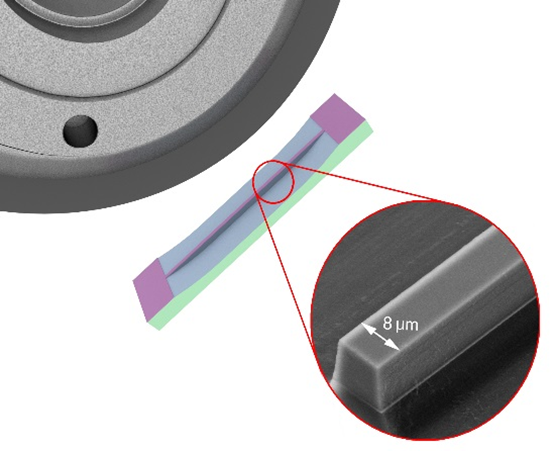

Precision dice & polish LiNbO3 ridge

Precision dice & polish LiNbO3 ridge

|

Thinning and release of glass microlenses

Thinning and release of glass microlenses

|

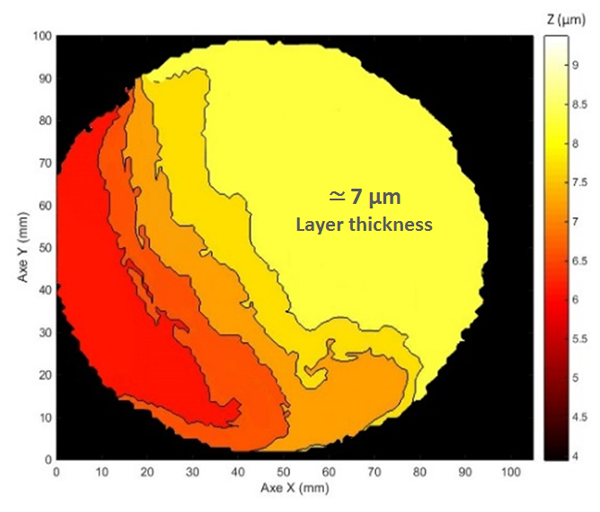

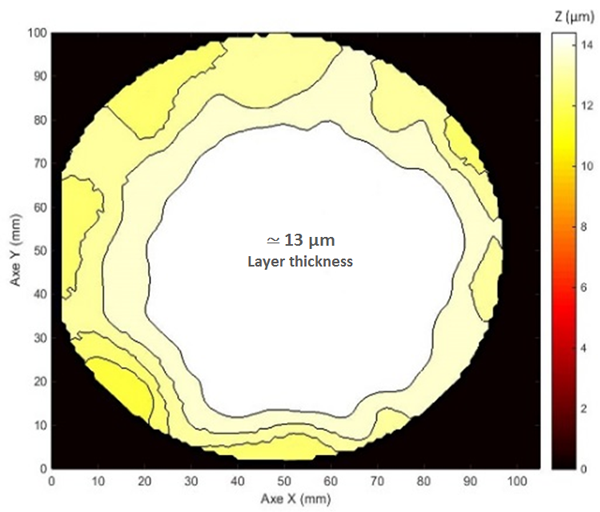

Layers of LiNbO3 / Si

Layers of LiNbO3 / Si> from thin (≃1 µm) to thick layers (hundred of µm)