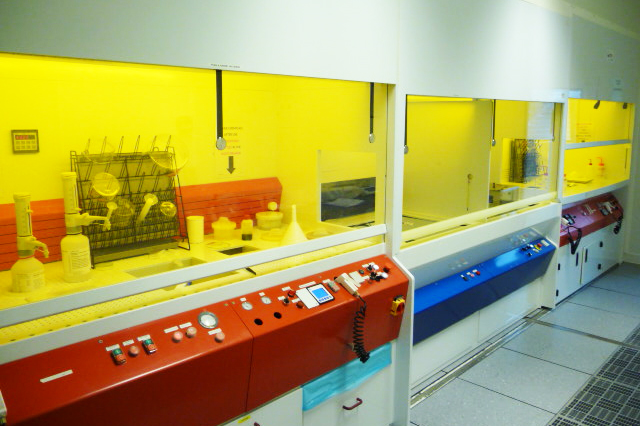

Wet chemistry

MIMENTO technology center has two rooms dedicated to chemistry where six main functions are performed:

- Surface cleaning: acid, base and solvent

- Surface preparation: essentially based on piranha

These two steps of cleaning and preparation are fundamental in the success of a process, because bad cleaning or bad surface preparation can lead to defects in the final results.

- Resist stripping for lift off process

- Wet etching: possibility to etch metals (Al, Ti, Cu, Cr, Ni, Au…) with selective etchants or dielectric as SiO2 with BHF solution

- Si patterns machining with KOH solution

- Electroplating of Ni, Cu or Au

Stirrers, hot plates and ultrasonic tanks complete the wet benches of these two chemistry rooms.

Resource contact:

| Laurent ROBERT 03 81 66 66 47 lrobert [at] femto-st.fr |

Personal page: https://www.femto-st.fr/fr/personnel-femto/laurentrobert |

| Marion VIEIRA 03 63 08 26 56 marion.vieira [at] femto-st.fr |

Personal page: https://www.femto-st.fr/fr/personnel-femto/marionvieira |

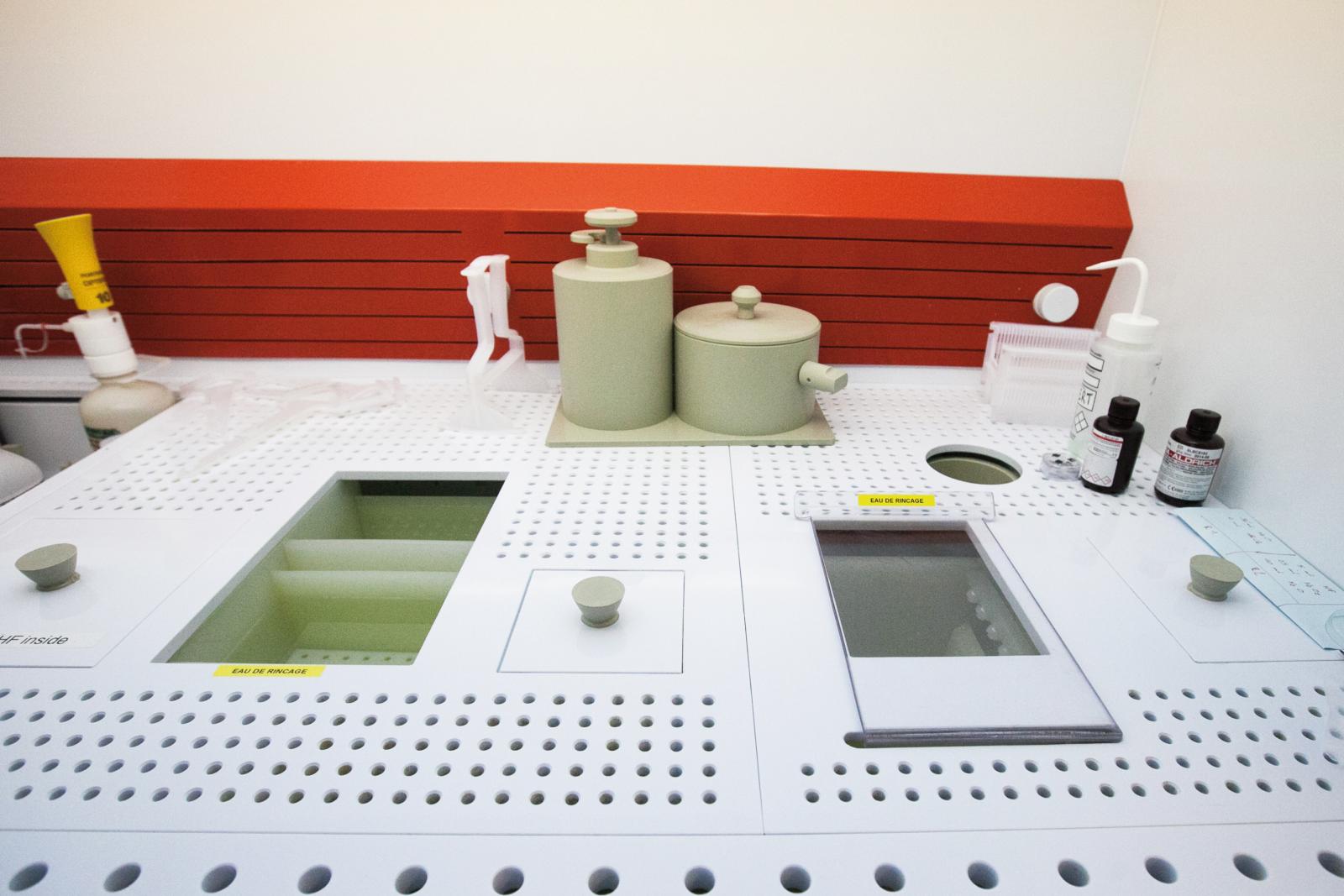

Hydrofluoric Acid Bench

| Idonus HF VPE-100 |

Use: > SiO2 and Ti etching > Vapor HF Etching |

|

Technical specifications |

——

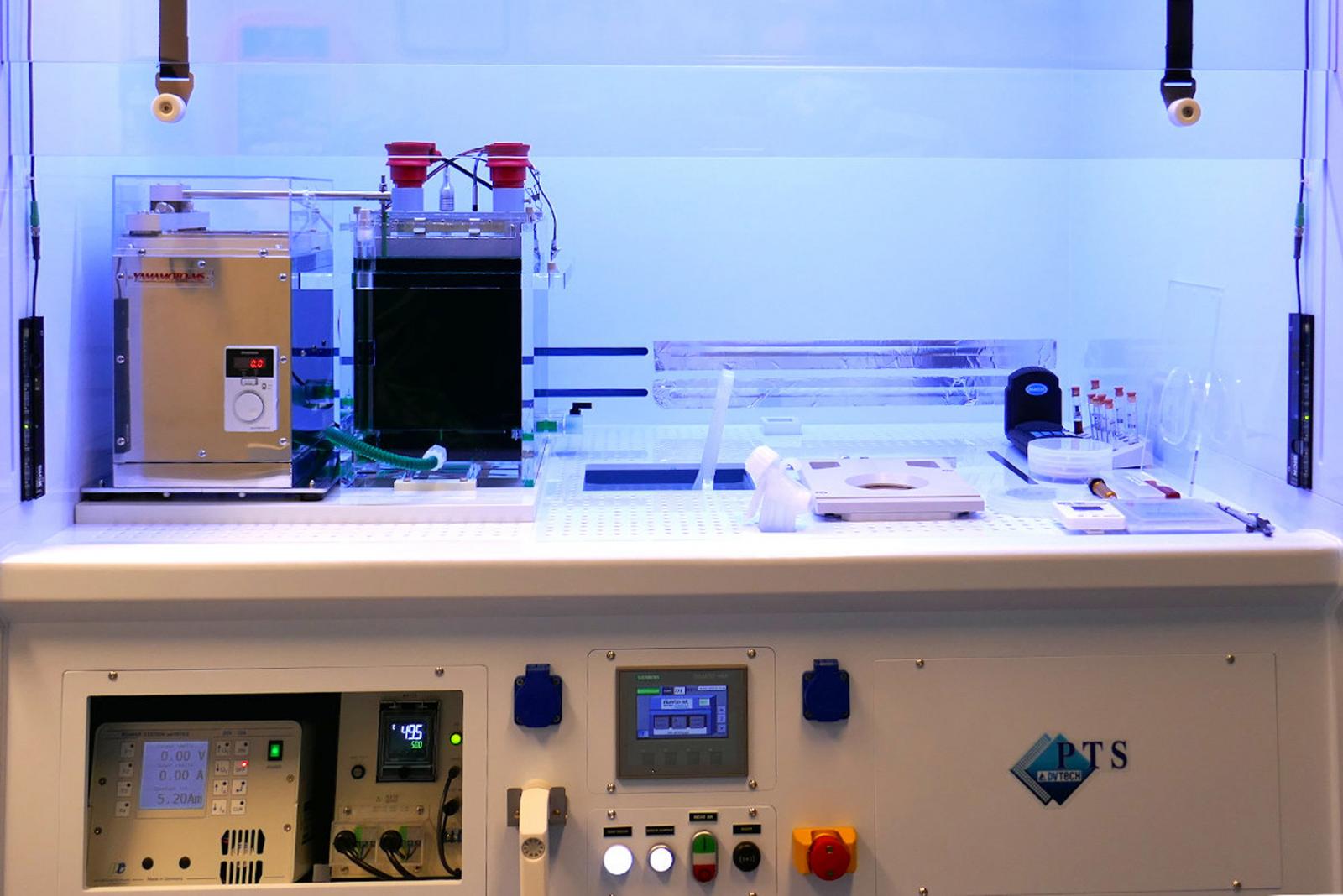

Electroplating Ni system

| Yamamoto station | Use: > Hard mask for etching > Items in nickel > Vias filling > 3", 4" and 6" wafers |

|

Technical specifications |

——

Chemical benches

| Acid bench Base bench Solvents bench |

Use: > Metals wet etching > Silicon wet etching > Photoresist stripping > Substrates cleaning |

|

Technical specifications (Acid & solvent bench) Technical specifications (KOH bench) |

——

Realisations

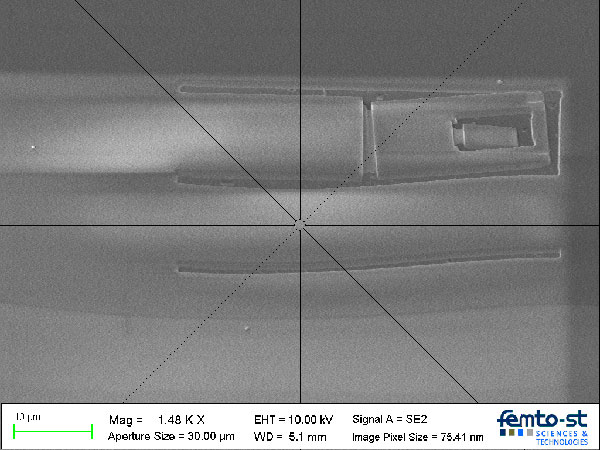

Ni electroplating

Ni electroplating

|

KOH wet etching

KOH wet etching

|