Industrial line

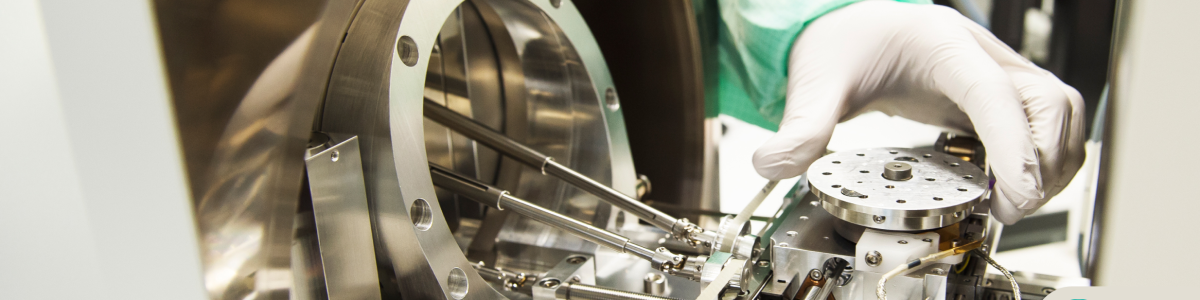

This industrial production line is managed by frec|n|sys, a spin-off of FEMTO-ST, and 100 % subsidiary of SOITEC group. Its activity is dedicated to the fabrication of micro and nano-acoustic waves devices (SAW, BAW) for RF filters, resonators, delay-lines and sensing systems. In that context, the company develops new competencies in the field of MEMS, particularly exploiting SOITEC POI (Piezoelectric-On-Insulator) wafers obtained by Smart-CutTM techniques and combining single crystal piezoelectric thin films and silicon.

The main characteristic of this project consists in the exploitation of this pilot line, halfway between research and industry. Unprecedented initiative in France, this technology platform provides high yield processes for industry-oriented scientific investigations and unique opportunities for combining front-end research results and market-oriented developments.

The pilot line covers 200 sqm in ISO 5 conditions. The main equipments operated here are a high resolution lithography body9 i-line stepper, automatic coating and development tracks, a sputtering cluster (AlN, Mo), a high accuracy evaporation machine (Al, Ti, Pt, Au), a ferroelectric poling bench, an O2-plasma cleaner, several characterization instruments (CD SEM equipments, profilometers, tip-probing station, microscopes) and chemical benches for wafer surface processing and cleaning.

Contact

| Sylvain BALLANDRAS: +33 (0)3 81 25 53 63 (CEO) |

Emilie COURJON: +33 (0)3 81 25 53 54 (Production manager) |

|

|

|

www.frecnsys.fr

Main equipments

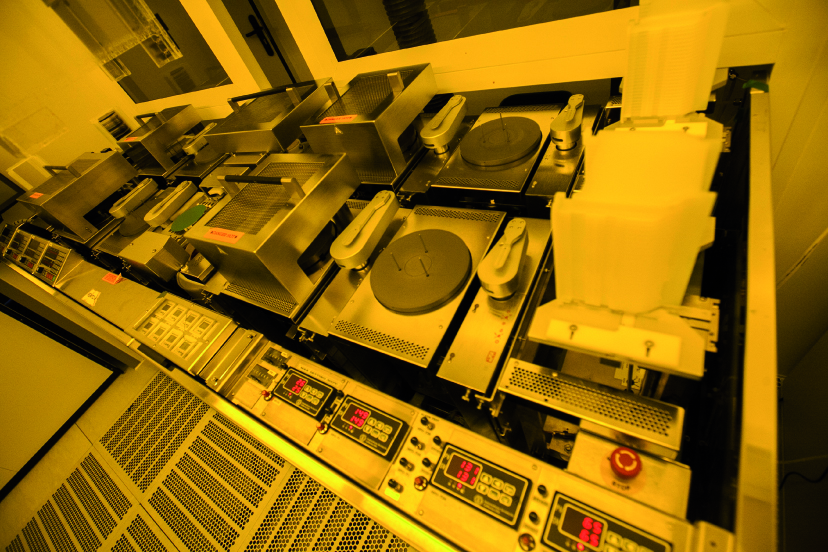

| SVG 88 series |

Use: > Automatic coating & development tracks |

|

——

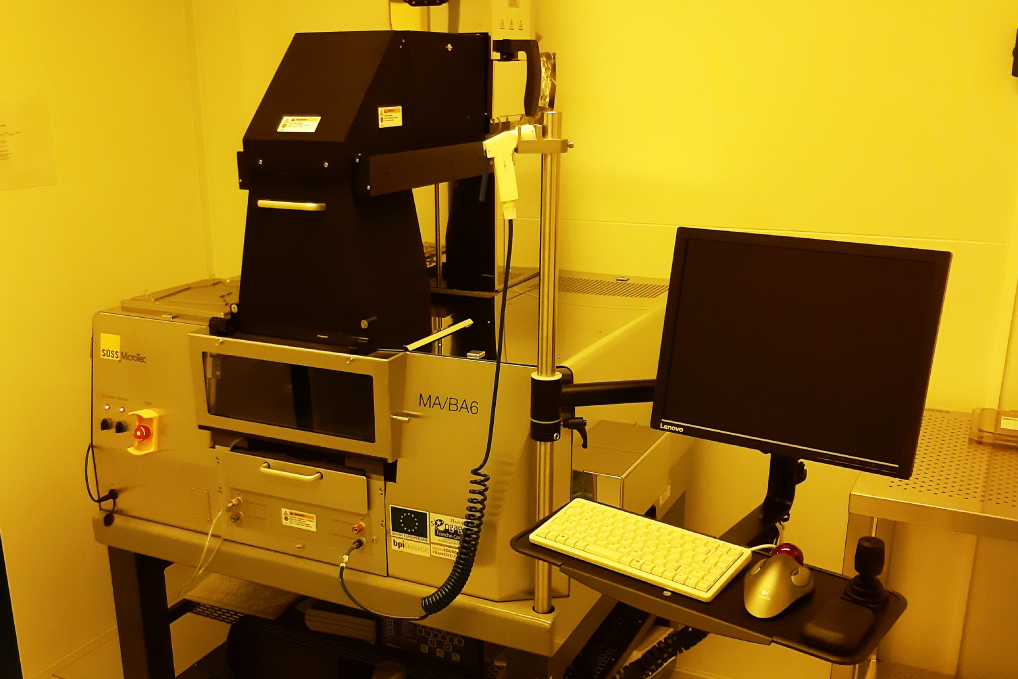

| Süss Microtec MA6-GEN4 |

Use: > DUV Aligner (Contact photolithography machine) |

|

——

| Nikon NSR2005i9C |

Use: > Stepper (High resolution lithography machine) |

|

——

| Trikon Sigma 200 |

Use: > Cathode sputtering |

|

——

| Balzers BAK760 |

Use: > Evaporation |

|

——

| Hitachi S9220, S8840 |

Use: > CD SEM (Critical dimension measurement system) |

|